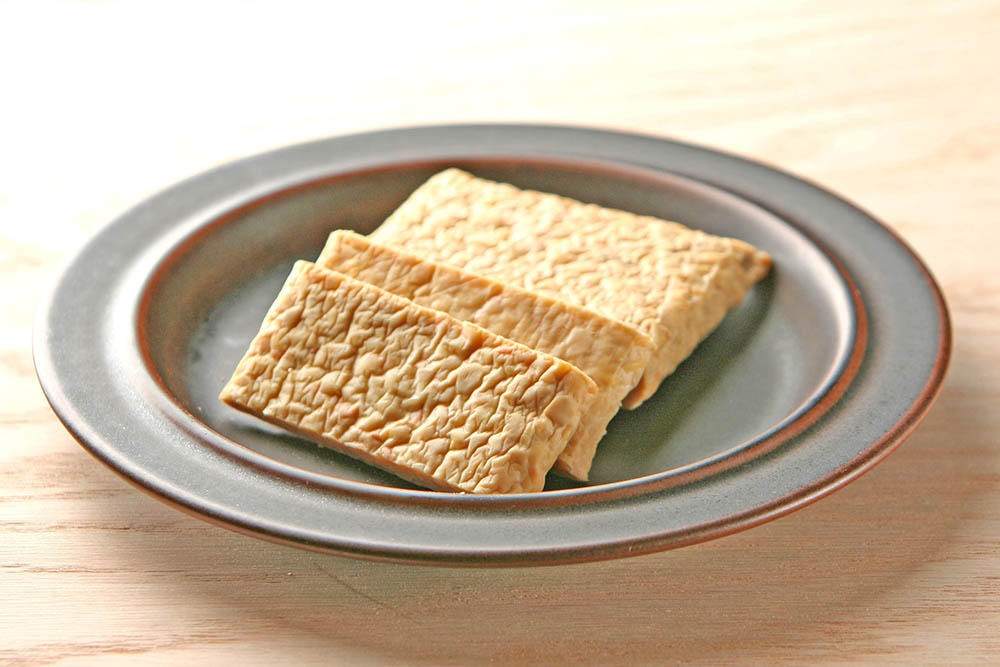

Over our 40 years in the natural foods industry, the conversation has changed – a lot. Each year, more people want to know about our policies and procedures, and about what we’re doing to make our business more sustainable. Given the current climate crisis, we think the reasons we started Northern Soy are more important than ever. If you’ve discovered SoyBoy tofu and tempeh recently, you might not know that two hippies (Norman Holland and Andrew Schecter) started making tofu because they envisioned a business to serve as a vehicle for positive social change. Those two hippies still enjoy coming to work every day at SoyBoy.

Sustainability at Heart

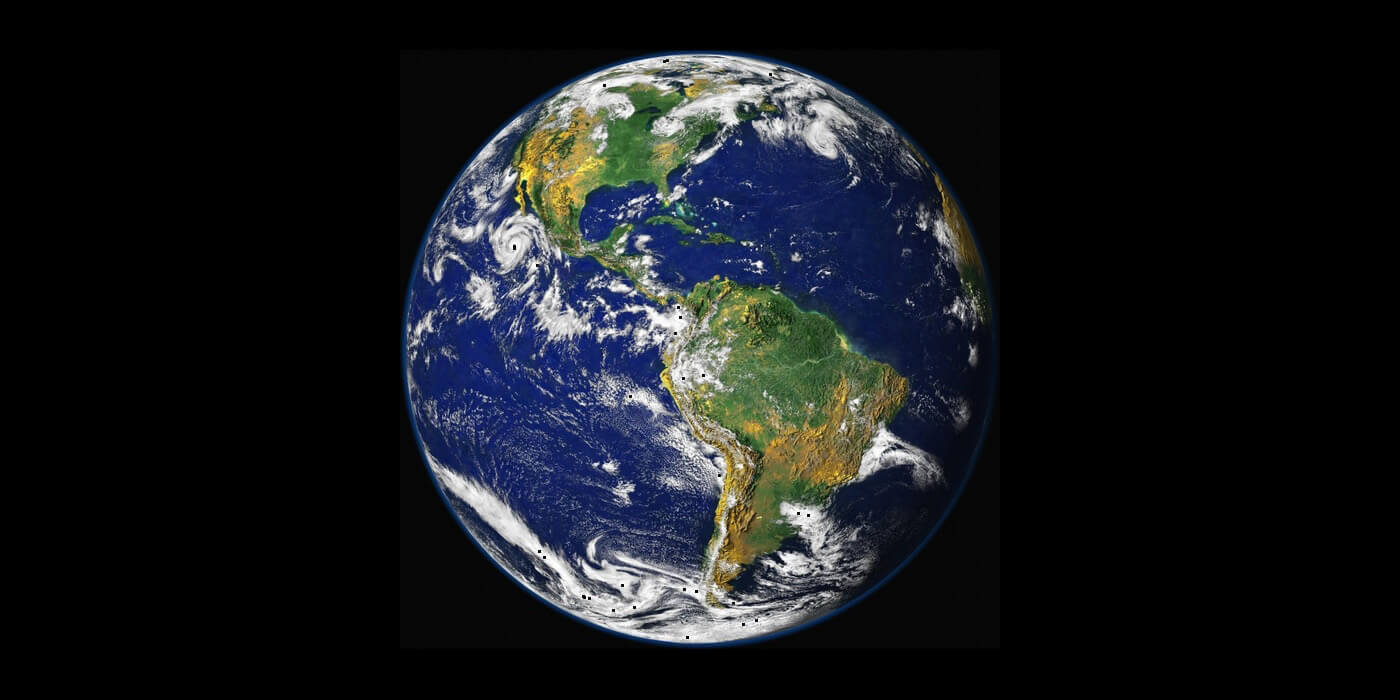

In 1977, no one was using the word “sustainability.” Frances Moore Lappe, author of “Diet for a Small Planet,” had recently begun spreading the word that vegetable foods were more ecologically friendly than animal-derived foods. We set out to make healthy foods for those following a vegetarian diet (ourselves included) and to create a workplace where people can enjoy their work and have their needs fulfilled. We chose organic tofu and tempeh made through traditional methods because they use a tiny fraction of the planetary resources required for animal protein. We’ve always pursued these goals in the most environmentally friendly way we were able.

Only Organic Soybeans

SoyBoy products have been USDA Organic since the program began in 2002. From our beginning, we’ve sought out soybeans grown through more sustainable means, without the use of fertilizers, that don’t put nitrates in our waterways, and that don’t use pesticides or herbicides. Today, the USDA Organic label means even more. Organic foods must be GMO free, so this certification gives freedom of choice to those wanting to avoid GMOs.

Local Sourcing

We regard supporting local organic agriculture and minimizing transportation as another means to improve the sustainability of our business. Staying close with the farmers who grow our beans – both geographically and through enduring relationships – has had many benefits. It reduces the fossil fuels consumed and greenhouse gas emissions created by the manufacturing of our products. It keeps dollars flowing into small farms that preserve the availability of American-grown Organic, Non-GMO soy. It connects those who eat our SoyBoy quality products to local ingredients.

The Biology of Byproducts

The tofu-making process creates two significant byproducts: soybean pulp (known by its Japanese name “okara”) and liquid soy milk “whey.” We’ve considered numerous methods for disposal or repurposing the millions of pounds of okara that we generate every year. Reviewing them all would take a separate blog post, but we found (for example) that (1) shipping okara as feed for animal sanctuaries, (2) composting, (3) spreading as fertilizer, and (4) fermenting to make methane just weren’t viable. We concluded that passing on this certified organic, nutrient-rich material to the local agriculture industry was our best, most conscionable choice. For this reason, we sell okara at the cost of transport to local organic dairy farmers, helping them to reduce their costs while also finding a home for our byproduct. When it comes to the liquid whey, we’ve been working for years with the New York State Pollution Prevention Institute (NYSP2I) and the local scientific community to develop a method to make our liquid byproduct a positive contributor to local agriculture and the environment. One ongoing goal is to convert this byproduct into biofuel, which would reduce methane emissions while helping power our factory.

Packaging and Pasteurization

A few of our most loyal customers (and some of our newest fans) long for the days when we sold bulk tofu in returnable buckets. Indeed, that reusable, minimal-waste packaging showcased our ideals and launched our company. But the critical need to pasteurize our products (to ensure food safety and adequate shelf life) made that option untenable. We’ve been working with packaging manufacturers to develop a suitable retail tofu tray that is compostable, properly protective of the tofu, and able to withstand the pasteurization process. The available options haven’t panned out yet, so for the time being, we package in recyclable polyethylene trays. The bulk tofu that we sell to restaurants, institutions, and commercial kitchens comes in large blocks sealed with the minimum: very thin, flexible plastic.

A Place for People

The idea that happy people make higher quality products is a conviction at Northern Soy. We consider maintaining a great workplace to be a matter of sustainability, too. All new hires start at a wage of at least $15/hour. In addition to a living wage, our employees receive health insurance and a 401K plan with generous matching, and we start them off on a retirement program so that they have a sustainable lifestyle. Our employees are a key factor in every decision we make, and we continually invest in the safety and comfort of the workplace.

About

We began as a tiny enterprise to promote a vegetarian lifestyle. Now we’ve grown into an environmentally friendly company providing excellent employment for more than thirty people.

Links

Contact

345 Paul RoadRochester, NY 14624

Phone: 585-235-8970

Fax: 585-235-3753